Mastery of the fourth state of matter, plasma, is a delicate and powerful balancing act, where even a slight change in gas pressure or power can ruin your entire process.

Traditional plasma R&D grinds progress to a halt, burning time and budget on trial-and-error experiments.

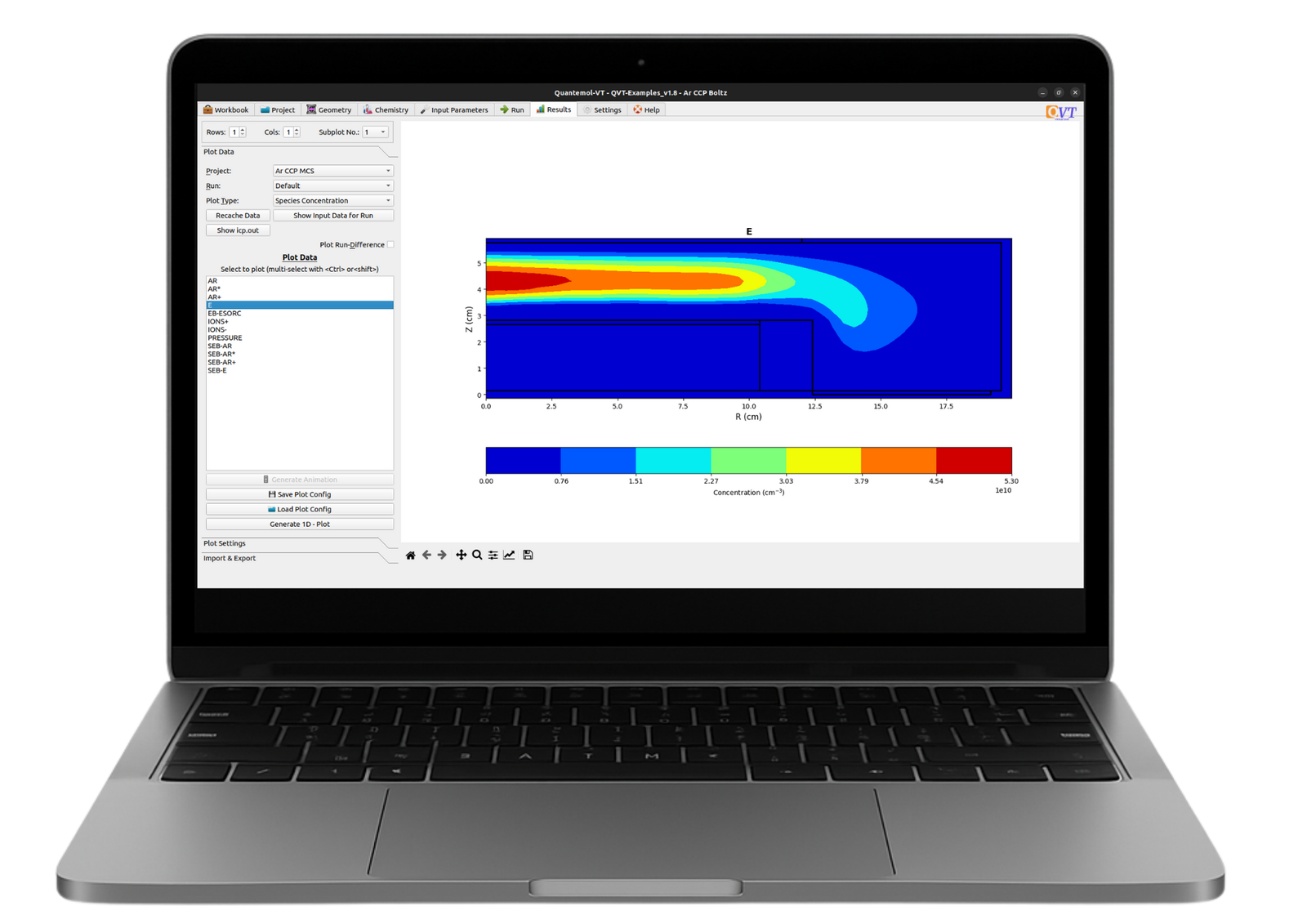

Enter Quantemol Virtual Tool (QVT), the expert software system built to streamline industrial plasma processing. Think of QVT as your high-powered, digital twin, ready to deliver deep insights into your process. QVT is optimised for simulating low-pressure plasmas, performing best in the 1 mTorr to 1 Torr range, which covers most advanced industrial applications. Higher pressure simulations are achievable but typically require more idealisation, such as of the geometry.

Why are users switching to QVT?

- Hybrid Power: Speed Meets Science. The biggest challenge in plasma simulation is striking a balance between speed and accuracy. QVT delivers “lightning-fast simulations” while precisely capturing the complex kinetic physics required for low-pressure plasmas. This balance means you get reliable results fast, completing large parameter sweeps in days, not months.

- Accelerate Innovation: The R&D Shortcut. By providing trustworthy digital insights, QVT allows you to run dozens of scenarios virtually, cutting R&D costs and streamlining your process development. The result? You get your breakthrough to market faster.

- Effortless: Designed for Engineers. Despite its robust capabilities, QVT is provided on an intuitive platform. You don’t need a specialised high-powered computer, nor do you need to become a computational physics expert to run your first model. The interface is designed to make complex setups easy, saving you valuable time.

Trust Is Built-In

QVT’s reliability is rooted in two pillars:

- The Engine: QVT’s core engine is the highly verified Hybrid Plasma Equipment Model (HPEM). This robust code was developed by renowned Professor Mark Kushner and his group at the University of Michigan and has been validated over decades against experimental data in countless publications.

- The Data: A simulation is only as good as its input. We’ve eliminated the headache of data collection by bundling QVT with a massive library of “validated plasma chemistries and cross-sections”. This chemistry data comes straight from the Quantemol-DB (QDB), ensuring your input is trustworthy and pre-certified.

QVT helps you precisely model critical metrics such as etch/deposition uniformity and analyse the crucial ion fluxes hitting your wafer surface. It’s the essential tool for optimising tool design and achieving process control.

Ready to gain deep, digital visibility into your process? It’s time to stop guessing and start simulating. Check out QVT today!

By Annie Laver

Annie Laver

SCIENTIFIC COMMUNICATIONS ADMINISTRATOR